Additive Manufacturing

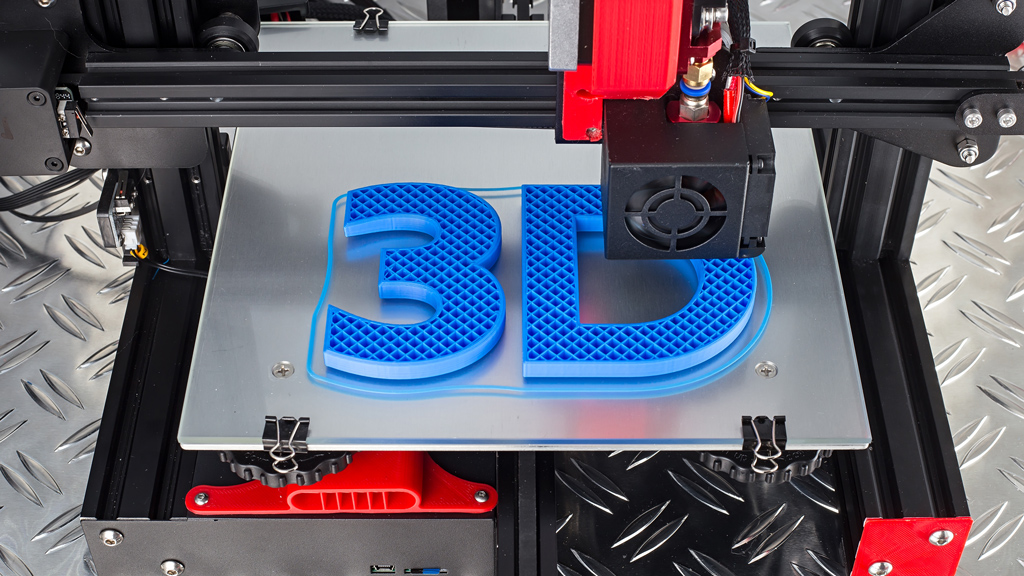

In recent years, additive manufacturing, more commonly known as 3D printing, has been a topic of conversation within the realms of art, business, technology, and industry. You may have heard about 3D printers in the news or online, and you may even know someone with their own small-scale 3D printer. So what is all of the talk about? What exactly is additive manufacturing and why is it so special?

Rather than more traditional forms of manufacturing where material is cut away or subtracted from a material to create form, additive manufacturing adds material layer-by-layer to create form. This allows for generally less material waste and offers many opportunities for interesting forms and complex geometry never before possible with traditional manufacturing means.

One aspect of 3D printers that is so unique and interesting is that the technology was developed without a clear direction or vision for all the purposes it would serve. Though additive manufacturing has been around since before the 2000’s, the extent of the technology’s capabilities has been left largely unexplored. This invites designers and other creative professions to uncover the technology’s untapped potential. Advancements in printing speed, printing fidelity, and material capabilities have opened the doors of possibility even further for designers to explore future applications of the technology.

It is at this point where I believe it best to introduce the great opportunity I have been given and the premise of my project.

Assigned Brief

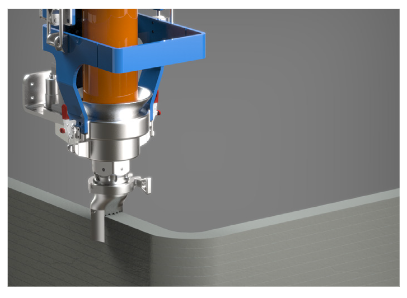

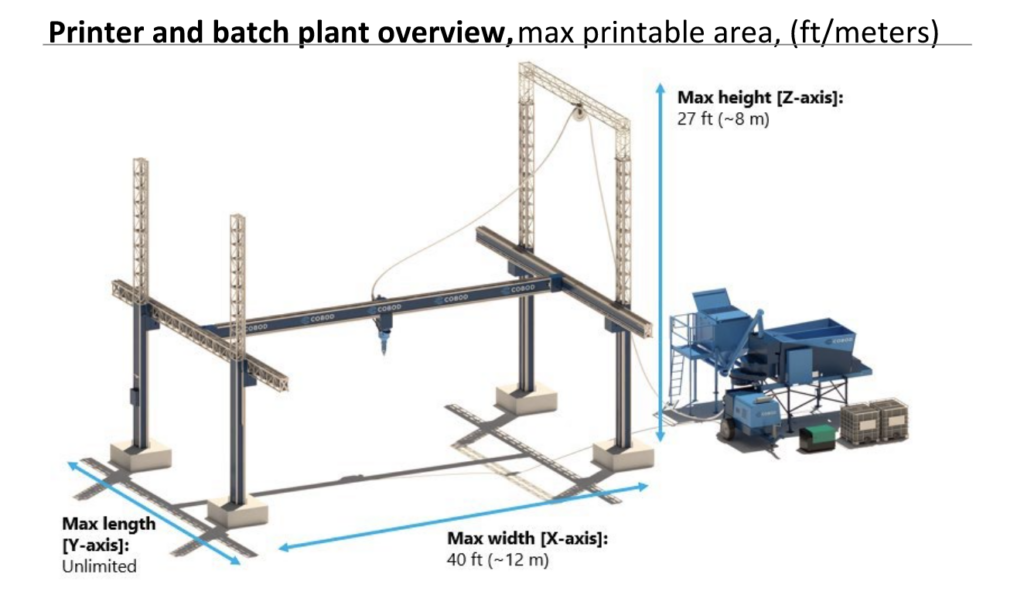

Ohio State’s Center for Design Manufacturing and Excellence, or CDME, has recently acquired a new piece of additive manufacturing technology; the COBOD-BOD2, a large-scale concrete 3D printer. With a printing area of approximately 20ft wide, 30ft long, and 10ft tall, this printer has the capabilities to print large sturdy structures.

In this project, I will be partnering with CDME to explore potential new applications of the technology. By performing speculative explorations and providing insights into the creative uses of the technology, I hope to contribute to the ever growing and expanding knowledge of concrete 3D printing and additive manufacturing technologies.

Unfortunately I will not have access to the printer until sometime after this project is completed, however I believe other machines and forms of additive manufacturing may serve the purpose of prototyping and learning for this project.

Primary Research_______________________________________

For my primary research I wanted to focus on understanding the material concrete, and look into concrete 3D printing as a whole.

Concrete Material

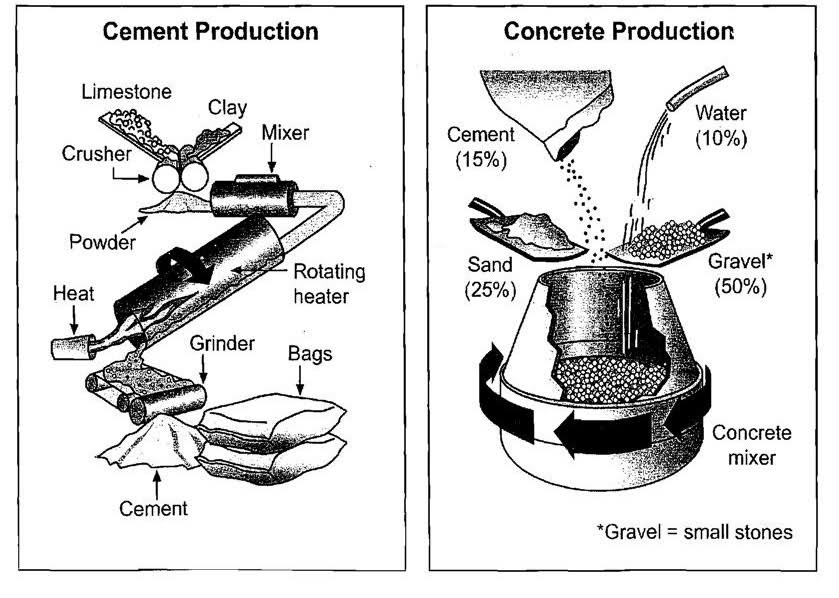

First let’s take a look at the material of concrete. Concrete is made from 3 primary ingredients. This includes: aggregate, cement, and water. The percentage of each ingredient varies however aggregates typically make up the biggest percentage. Aggregates help bind the concrete together and they range from fine to coarse. Common aggregates include sand, gravel, and other crushed rock. While there are a variety of different cement mixes all offering slightly different properties, the most commonly used mixes feature tricalcium silicate, acetylene sulfide, tricalcium aluminate. In essence they primarily use a mixture of lime, silica, and alumina with trace other elements. Concrete is made through a process of mining, crushing, drying and grinding, and sintering.

Concrete is a very popular building material due to its durability, and low cost. In fact, it is currently the most commonly used building material globally. It is generally considered to be highly sustainable due to its success at resisting fire, weathering & erosion, rotting, and rusting. It also is a good insulator and takes time to heat up and cool down. This means it is helpful in keeping a house warmer in the winter and cooler in the summer. But despite the sustainable properties it lends, there are a few downsides. Production on such a large scale has had harmful effects to the environment. It is reported that its production alone generates roughly 8% of global CO2 emissions. It is also an extremely dense and heavy material. Making transportation difficult at times.

Concrete Material Exploration

I also took it upon myself to understand on a deeper level the material of concrete. I explored various ways to add pigment to concrete and came to understand just how heavy the material is.

3D Printing Concrete

Next, looking into concrete 3D printing, it became apparent right away that this technology is used primarily for architecture and house construction. This is no surprise considering the material and scale, however I had to wonder if there were other uses. The technology seems to lightly dabble in outdoor furniture construction, however I have seen very little application outside of those two areas. With such an interesting and exciting technology, I wonder if there are unseen opportunities here for a new application or market venture.

According to the website, the COBOD-BOD2 is the fastest concrete printer on the market with the ability to print up to 1000 millimeters per second. It also has the ability to print on a 4D axis. This means it can move left/right on an X axis, up/down on a Z axis, forward/back on a Y axis, and the nozzle has an axis of its own allowing the head to rotate in a circular motion, allowing for smooth and curving strokes.

The printer takes between four and six hours to assemble and requires three to four people to operate/attend it. Computer software operated, a CAD model can be made reality layer-by-layer relatively quickly.

While this technology excels in a number of areas such as speed, precision, and developing custom forms, there are certain areas where the technology struggles and is not quite as strong.

The biggest obstacle with Concrete 3D printing are overhangs. Plastic 3D printing handles overhangs relatively easily with the help of support material. Overhangs are filled in with thin and weakly connected material to support overhangs, which is later removed. Concrete 3D printing does not have this option. Concrete will stick to and harden over any support material and will be impractical if not nearly impossible to remove. However, concrete will sag and cave-in anywhere it is not supported. To get around this fact, temporary supports may be added, or permanent metal inserts to be placed on overhangs in construction such as doorways and window frames. Another possible way to get around the difficulty of overhangs is to pre-fabricate (pre-fab). Unique and curving forms may be printed on their side, then, once dry, rotated up-right.

Another aspect that is often seen as a downside, though not always, is the layered appearance the print retains. The striations can be minimized through the use of flaps placed on the sides of the printer nozzle, however there still remains trace signs of striations. When it comes to the appearance of the layered striations, there is some debate but what it really comes down to is beauty is in the eye of the beholder.

Finally, it is important to note that this is a large-scale 3D printer. Therefore it excels best at large forms and features and struggles with small features. Intricate details would be quite difficult to capture without increasing the overall scale of the project. I suspect this limitation, paired with the fact that the housing market is always growing, is the primary reason why the technology is used for construction almost exclusively.

Public Opinion Survey

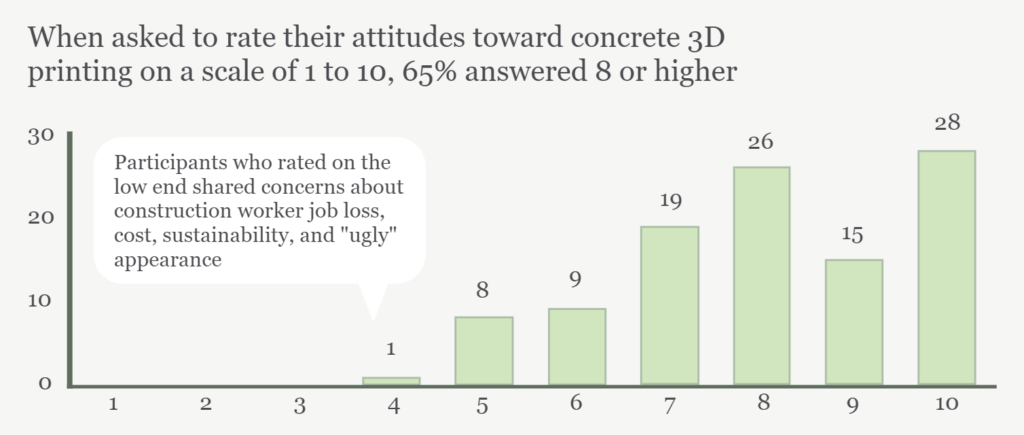

To understand public opinion on the technology and to gain some understanding of social needs and desires, I sent out a 10 question survey. Of the 106 participants, over 75% identified as female and a majority were between the ages of 20 and 25. I would like to highlight some key questions I asked and the feedback I received. The full survey results may be found under the numbers section of this newspaper.

I asked for participant opinion and attitude toward concrete 3D printing. Most participants felt generally positive toward the technology, however unsure about its level of sustainability, its cost, construction worker job loss, and its appearance. The appearance seemed to be a main concern with many people not completely sold on the layered striations look.

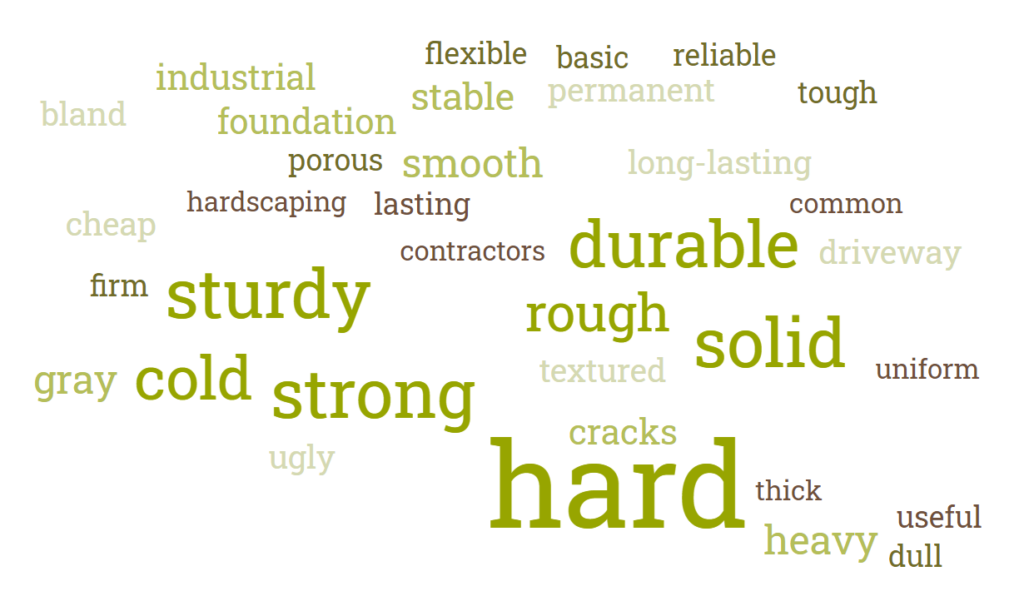

I asked participants to describe concrete using 3 of their own words. The results revealed that people saw the value in the material’s strengths and viewed concrete as useful and necessary, but found the material to be dull and lifeless.

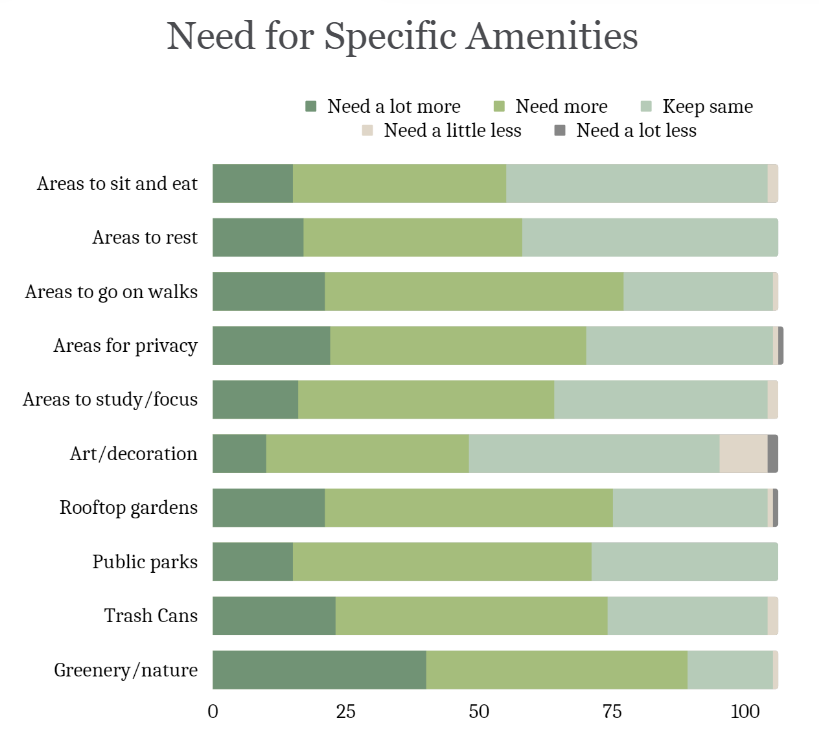

I asked participants to rate how highly they felt urban environments needed to have various different amenities. Among these, greenery/nature and areas to walk were rated most highly.

In summary, this survey revealed to me 3 major insights. First, people (at least according to this sample size) generally feel positive toward concrete 3D printing technology, but have concerns about its cost, sustainability, and appearance. Second, people perceive the material of concrete to be sturdy, useful, and necessary, but find it to be cold, dull, and lifeless. And finally, people want to increase their engagement with greenery and nature in urban settings.

These insights prompted questions like;

- What can be done to make concrete 3D printing more sustainable, cost effective, and visually pleasing?

- What can be done to make concrete feel less lifeless and dull? Can something be added to concrete to make it feel more warm, welcoming, exciting, and alive?

- How can urban spaces incorporate more greenery and nature?

I considered, and came to the realization that the last question actually answered at least part of the first two. How can concrete 3D printing be made more visually pleasing, welcoming, and exciting; the answer – greenery and nature/plant life.

Secondary Research ____________________________________

Greenery, nature, and plant life offer a number of benefits to urban environments and its inhabitants. Beyond beautifying a space, greenery improves air quality and can act as a sound barrier in the bustling and loud city. In addition, studies have shown that exposure and interaction with plant life can improve attitude and increase productivity. Increased exposure to plant life has even been linked to lower mortality rates and longer life-spans.

Despite the benefits, I observed a few things about greenery and its relation to urban settings. First, greenery is often treated as decoration and not a destination. Raised flower beds, trees, and other small installments are flat and do not encourage people to stay to enjoy them. They exist only to beautify the space.

And when greenery is made a destination, it is often placed out of the way and receives little attraction because of this- such as rooftop gardens or traffic circles. Many of these locations also fail to keep people coming back due to poor seating and overgrown conditions. It seems there is a balance to be found when it comes to designing elements of nature into a man-made and human-centric environment.

I decided to focus my project on introducing greenery and plant life back into the urban environment through the use of concrete 3D printing.

Knowlton Rooftop Garden Observation

I began my secondary research by visiting a current green space in the urban setting – Ohio State’s Knowlton Rooftop Garden. I took notes on the experience and developed a map of the space.

This observation prompted me to think about the importance of considering various aspects into my project such as ease of accessibility and providing seating.

Urban Trends

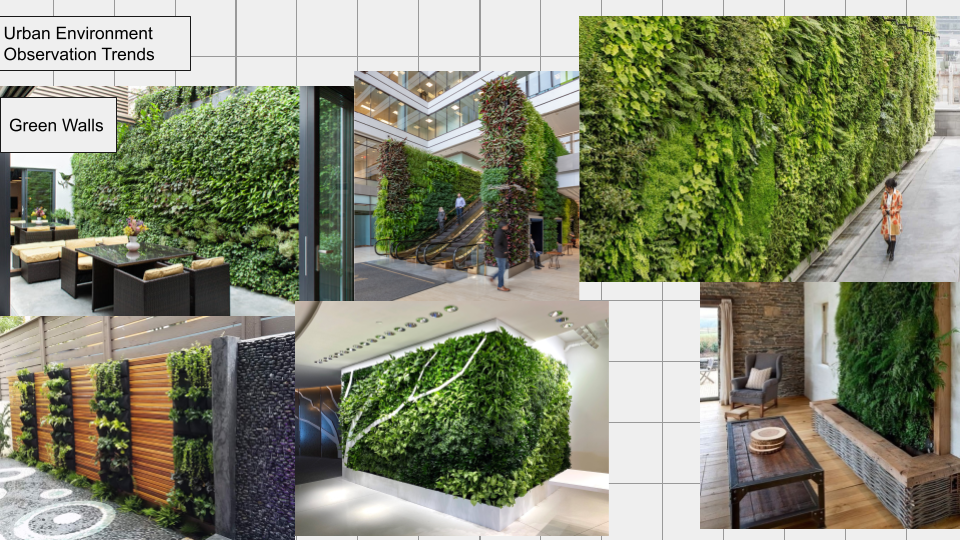

In order to gain an understanding of what might be perceived as useful, cool and successful, and fit flawlessly into the urban setting, I also observed trends in urban green spaces and in urban style.

Rooftop gardens, green walls, and parklets have all become very popular in urban environments in the last few years. Analyzing what is similar between these structures led me to an important insight about urban spaces. The reality of urban spaces is that very little space exists, therefore vertical space must be utilized.

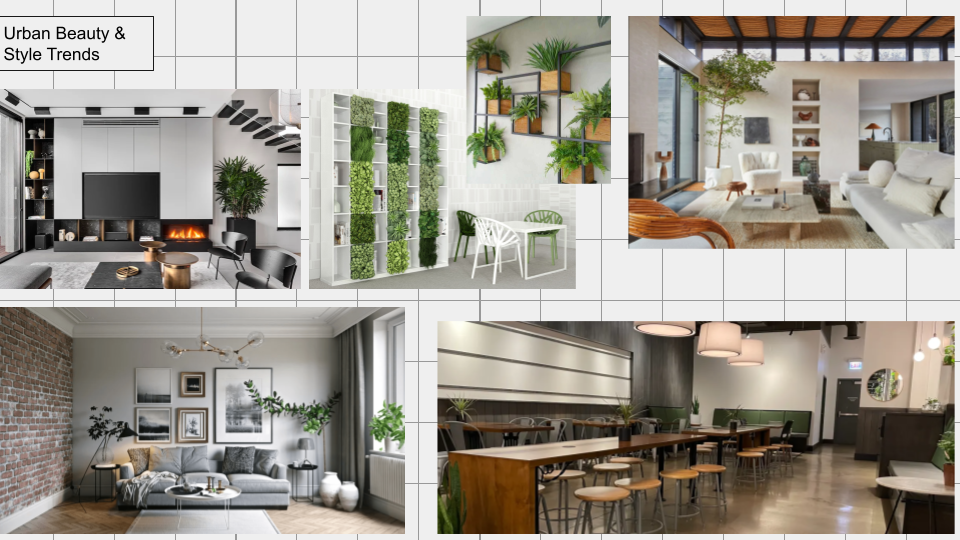

I looked at urban interior design for style, form, and material inspiration.

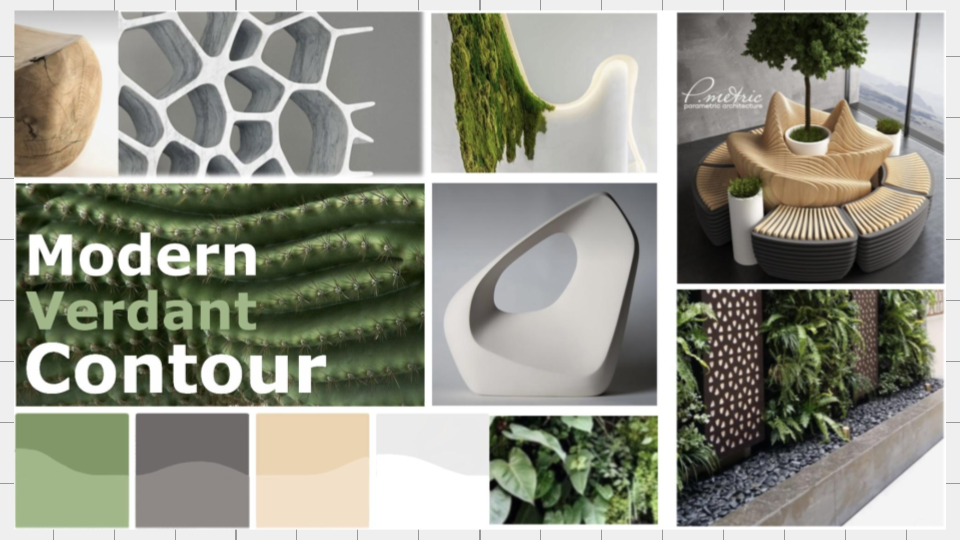

I developed a Mood Board to help guide my project design.

My secondary research will continue to evolve and explore new areas throughout this project.

Design Brief __________________________________________

Through my research, I have identified a number of problem areas. First, is the fact that most people find the appearance of 3D printed concrete to be less than desirable. If people find the results of the technology to be unattractive, people are less likely to subscribe to the technology and it becomes difficult for the technology to advance further. Second, concrete’s level of sustainability is questionable. Concrete comes with a rather high embodied energy – or a high level of carbon emissions involved in its creation. Third, Urban areas do not contain enough green spaces and plant-life. Existing green spaces often lack locational convenience, lack quality care, and lack consideration for human engagement. Overall, urban green spaces often do not invite people in and are designed in a way that does not encourage them to stay.

The first and primary opportunity is to beautify the urban landscape. Cities are often referred to as “concrete jungles” and lack green spaces. The opportunity to add plantlife and greenery in order to beautify the space is a very real and valuable opportunity. Secondly, there is the opportunity to implement some curved and organic forms into an otherwise “blocky” urban setting. Buildings and architecture within cities often follow a pattern of straight edges and sharp corners. What would be the effects of implementing structures with softened edges and gentle contours/curves? Next, there is the opportunity to explore lightweight and more eco-friendly alternatives to traditional 3D printing concrete mix. Perhaps there is the opportunity to limit and reduce the amount of concrete used. Finally, there is the opportunity to expand into vertical spaces. This will not only conserve space, but encourage people passing by to look up and to enjoy the beauty of nature and engage with the people around them.

My problem statement comes in the form of a question. The question to be asked is this; “How can concrete 3D printing be used to develop infrastructure for plant life in urban spaces that is inviting and accessible, but not in the way?” And as a follow-up thought, “how can the creation of this infrastructure enhance public perceptions of concrete 3D printing?”

All my research thus far has directed my development of my design brief. And my design brief has brought me to this final overarching goal. Urban environments lack the space and infrastructure required for the public to engage with nature on a daily basis. Utilizing the COBOD 3D printer, I will develop a green wall seating unit to support and facilitate both plant life and human engagement within the urban setting.