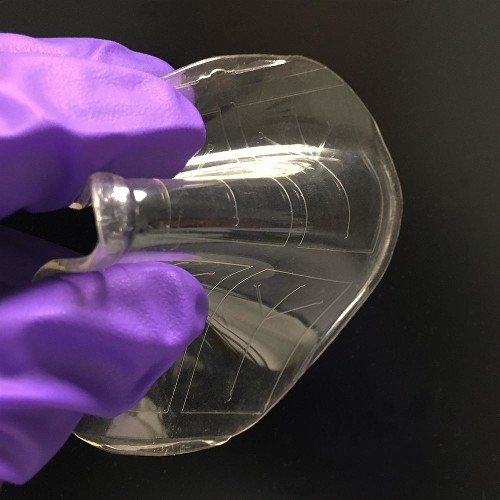

Material selection is a crucial part of the design process in the development of microfluidic devices. An increasingly important factor in material selection is the issue of sustainability, stemming from a greater awareness of human impact on the environment and a growing urgency to minimize this environmental impact. Sustainability is relevant to microfluidics because the research field and the commercial market are both expected to grow rapidly, and more microfluidic devices will be manufactured, consumed, and disposed as these technologies scale in production. Disposability is frequently raised as an advantage of microfluidic devices with small device footprints, low material costs, and high manufacturability, but does not address concerns related to sustainability. Importantly, in comparing thermoplastics and poly(dimethylsiloxane) (PDMS), a major distinction between them is that thermoplastics are generally recyclable, while cured PDMS is not. An investigation into whether recycled plastics can be used for microfluidic devices in a laboratory setting is thus an important initial step towards determining the feasibility of incorporating a Design for Sustainability (DfS) approach with microfluidics. Here we report a novel method for recycling thermoplastic microfluidic devices in a laboratory setting. The recycling process was repeated multiple times, and each iteration yielded devices with high optical quality. The recycled devices were found to be suitable for cell biology studies, exhibiting good characteristics for supporting cell attachment, viability, and proliferation for commonly used cell lines. The recycling procedure is applicable to other thermoplastics, and the results obtained in this study suggest that recycling may be a feasible strategy toward more sustainable, “green” research, at least in a microfluidics laboratory setting.

Analysis:

In considering the Ecological life-span of these products, there needs to be consideration of end life of the bandage adhesive as well as the sensors themselves. Because the product is only used for a week, the life-span is short for such a hard to destroy technological element. This article considers whether using recycled plastics to create PDMS (microfluidic devices) is possible in the near future as current sensors are not recycled at all. This distinction will determine if it is beneficial to use compostable or recyclable adhesive along with the sensor.

Source:

Wan, A. M. D., Devadas, D., & Young, E. W. K. (2017, July 5). Recycled polymethylmethacrylate (PMMA) microfluidic devices. Sensors and Actuators B: Chemical. Retrieved October 25, 2022, from https://www.sciencedirect.com/science/article/pii/S0925400517312182#:~:text=Results%20from%20this%20study%20showed,recycled%20devices%20without%20significant%20differences.