Curbside pick-up rose in popularity as a service during the Covid-19 global pandemic, and has only continued to rise in popularity. As many news articles report, the service only continues to grow in popularity because people have come to see it’s benefits as an essential part of their daily routines. While the current curbside service was observed by myself and reported by several news articles as an extremly fast and efficient service, it isn’t without it’s issues, and there is oppournity for improvement in both the service and cargo areas of vehicles.

The rise of EVs and Autonomous vehicles goes hand in hand with the service, as the popularity of EVS grow so does the need to have practical and caring designs that attend to the multiple and diverse needs of buyers today. Companies like Ford and Tesla, who are expanding on the EV market much like many other manufacturers, have rolled out new features in their vehicles, like the frunk, to privde customers with more places to store their things. Companies that build EVs are building vehicle with new opportunities to re-invent the use of their space, and companies like Ford are jumpning on this train with the addition of frunks, front trunks that is, than can easly be packed with ice for example and used like a cooler, and later drained for the convenience of the owner.

The market is still developing and experimenting with how EVs turn out and how they will need to meet the needs of future buyers, and that is where it ties in with the curbside pick up service. EVs with their lack of mechanical parts and engines, feature large flat surfaces that now offer additional storage spaces for owners, and people are starting to take advantge of these spaces when they go shopping. Trunks are coming in with added space and hidden compartments, which are proven beneficial for customers who frequently carry items in their trunk. While added space is essential for the growing market, it is not a one solution solves all type of situation. After doing some intial primary research, I found that there are oppoiruntities for manufacturers to bridge several gaps in the cargo areas of their vehicles to assist with the shopping experience.

I have partnered with Honda R&D, a world renowed manufacter of vehicles that is lokking for a concept that will improve the asstive qualities of the cargo area in their future EVs and Autonomous vehicles.

To start out my research venture, I looked into secondary sources that could provide me some intital insight into areas where the service is lacking, and where the cargo areas of vehicles proves useful and any gaps were improvement is needed.

The rise in popularity of the service has prompted larger companies like Walmart to expand on this service, providing options like having a delivery service direct to house and even having someone pack the groceries directly in your fridge, and utilizing autonomous vehicles to deliver orders direct to your doorstep. While these services are trying to take a of the experience away from the customer, many have shown that they still prefer to use the traditional service model of ordering on the app and going to the store to pick up themselves.

I also also took note of issues where customers identified issues with accountability and order accuracy in several news articles, which led me to come up with a conjecture where technology built into the vehicle itself can bridge the gap of service accuracy and accountability of product delivery.

In this example, a delivery employee is packing groceries and a sensor inside the car, derived from sensor technology similar to the one Amazon uses in their new Amazon Stores, scans items in the bags as they are placed in the car to confirm that the orders are correct and the specific items ordered are in the order. Another component is that later this technology could be used to measure the quality of produce the order is providing, another common complaint about the service.

I completed primary research efforts in the form of surveys and interviews that conluded that a big hinderance for people wanting to use the service is the ablity of not being able to select their own produce. A lot of responses mentioned that the produce is not to their liking, and is not ripe enough or the produce has bruises or visible damage. And not only that, but customers also reported that produce and other items like milk and eggs are not always packed well with other items and are often left loosely packed in other bags or outside in the cargo area, where they roll around during the drive home and get damaged or damage other items, and get lost inside the car in crevices and gaps in the seats.

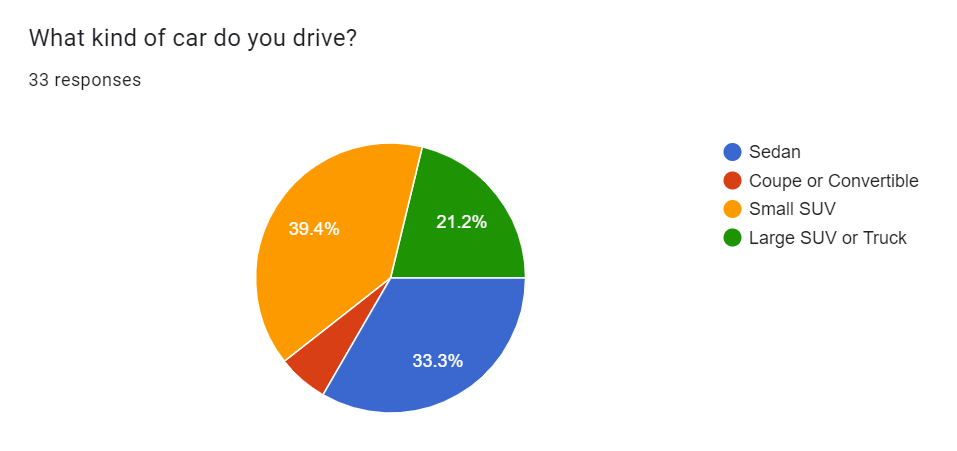

Another commonality found with online secondary sources and my primar research efforts is that there is a rise in consumers prefering to buy SUVS, Trucks and Vans as their vehicle of choice. This is echoed in my survey response where 60% of respondents said they use an SUV or Truck to pickup their groceries. I also completed ethnographic research that confirms this, as about 80-90% of the vehicle is observed using the service at different Kroger and Meijer stores were primarily family sized SUVS, Trucks and Vans. Sedans and small hatchbacks were the minority here. These reports align with Honda’s own vehicle sales, where I spoke to Kal from Honda R&D and he reported that the majority of their US sales come from their SUVS and Vans. Their plant in Ohio actually focuses primarily on the prduction of their SUVS for both their Honda lineup and also their premium brand Acura.

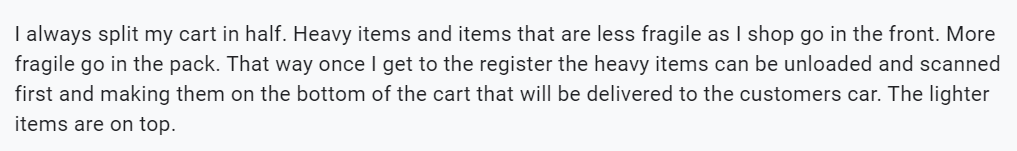

While trunks in SUVs offer a larger space for customers to sort items in the back, which can help explain the popularity with families and individuals who require more space than the average sedan, I found in my reserach reports of issues with organization. Common complaints had to do with how to organize the trunk of their car, and how they pack their bags. Customers also had concerns with packing frozen foods with other items, and most importanly fragile items not being secured properly or surrounded with enough protection to maintain their integrity. In one of my interviews with one of my participants, he reported that he had used his newer Honda Pilot to pick up some groceries curbside. One issue he found was that the employee packed his groceries in an organized fashion, that is, he said he had tomatoes packed in with laundry detergent, which damaged his priduce on route to his home. He also mentioned that when he shops for himself, he tends to place large items torwards the back and smaller items and bags in the front, because loose items tended to fall between the gaps of the rear seats and get lost or damaged, and this prevented his groceries from getting damaged. Typcially, employees at groceriy stores don’t have the customer’s preference on how they like to have their groceries packed, which can lead to issues as reported by several of my participants that I interviewed. I also observed this when I completed my ethnographic research, as I commonly observed employes packing large loose items like soda boxes and laundry detergent bottles next to small fragile bags filled with produce or things like eggs and packaged liquids.

I can confirm that through several of my interviews with employees, most grocery stores do not require employees to pack items a certain way. For example, I had a manager from a Meijer store who works in the curbside delivery department explain that they do not have a set process with what items can be packed together, she told me the only mehtod she uses is that she packs the items in a way that she would pack herself if she was grocery shopping.

Genrally, the employees I interviewed had a lot of expreince and had knowleadge on how to pack items effiecently, however that may not always be the case with most deliveries.

I think the biggest issue of all, has to do with employees having to work around items that were in the customer’s trunk to begin with. Some of the employee reponses were that they felt bad about having to pack items in trunks with other items already there, and I observed this first hand when I visited several grocery stores. In the image above, you can see two SUVs with items arready scattered in the back, getting in the way of the groceries being delivered. Not only is this an issue for the customer, who may not have enough space to carry items, but employees who have to work around this.

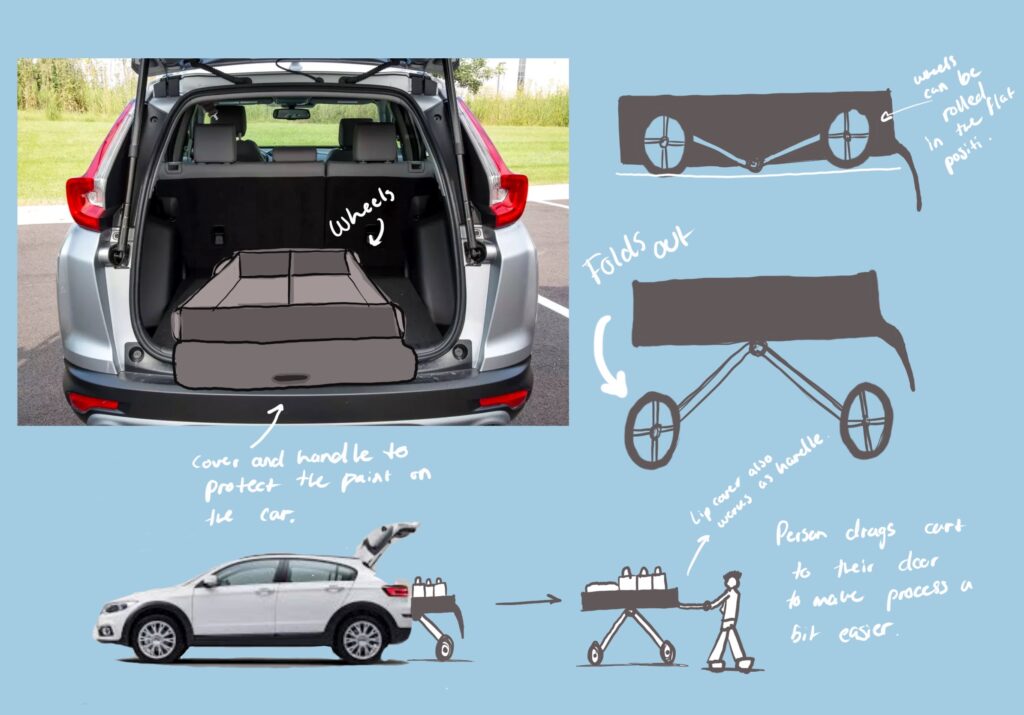

Because of these findings through interviews and from reading articles about expanding space within vehicles of the future, I came up with the conjecture of a portable flat pack organizer that expands and coverts into a trunk organizer that both customer and employee could benefit from.

The last paint point that I though was that customers reported physcal strain having to take groceries form their vehicle to their their home. I also observed physcial strain on employees who had to pack groceries into a vehicle. I observed an employee at a Kroger having to bend over to pack bags in a Jeep because he couldn’t lift up the rear window of the customer’s Wrangler. The customer actually had to get out to help the employee with the rear window and pack more groceries in. As far as customers go, they also explained they felt they hated going grocery shopping because of the last step in their journey, which was to unpack everything in their vehicle and take it into their home. This led me to two similar but different conjectures that explore storage organziation and trasportability.

In this example, issues with organziation, and ease of transport are explored. I made this conjecture because of the common issues with customer responses about the issue, and the things I observed while taking my notes at different grocery stores. I also want to explore how materials can be implemented here to add to accesories such as this, like plastics made from recylced carbon or carbon captured form the air. This concept was also inspired by new exploration in tech such as from the Renault Company in France who developed a concept that can stretch on demand to make itself longer. while still a gimmick in that concept, the idea of expansion and conversion where important for me to explore.

The next step is to develop concepts that combine features to help customers and employees with orgnazation and relieving physical strain. An added featue that I also want to explore is the sensor technology to help with order accuracy.