Keeping ahead of the curve in any field implies working on innovative new solutions. BMW and the Massachusetts Institute of Technology Self-Assembly Lab announced the unveiling of a new type of material, the first of its kind, which should help in the future in a variety of fields. According to the two companies, this is the first printed inflatable material, a technology that self-transforms, adapts and morphs from one state to another.

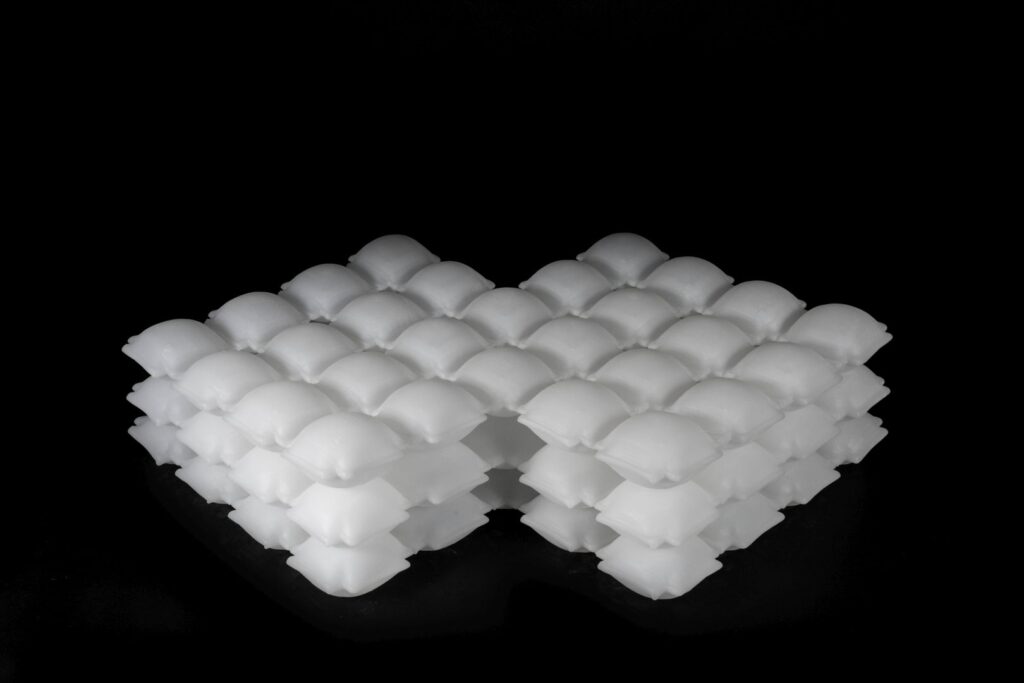

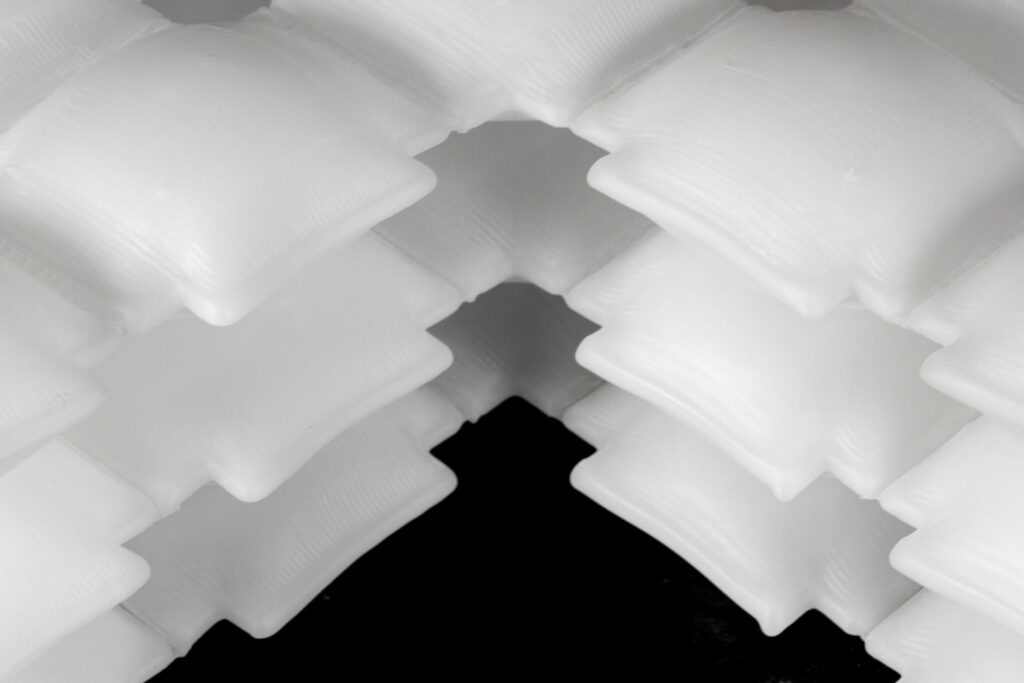

The BMW Design Department and MIT’s Self-Assembly Laboratory have started their cross-disciplinary study two years back with the mutual ambition to push the boundaries of material technologies. This collaboration resulted in the first example of a fully printed inflatable that can be customized to any size or shape. The silicone printed object can change shape depending on the amount of air pressure in the system. The pneumatic controls in the system allow the printed structure to transform into a variety of shapes, functions or stiffness characteristics. After testing various directions on how a visionary interior could take shape, the Self-Assembly Lab achieved a breakthrough when they managed to liquid print air and water-tight inflatable geometries, like customized printable balloons. Designers at BMW with new knowledge of this technology are eager to move away from our current understanding of car interiors as the forces reshaping the nature of transportation are eventually shifting toward a kind of vehicle that defies conventional front and back seats.

“There is no need to lock the car of the future into any particular shape. Interiors could even take on malleable, modular uses” says Martina Starke. This is why the study is fully focusing on technological dimensions and material properties at this stage.

Skylar Tibbits, founder of the Self-Assembly Lab explains: “We then brought together a number of recent technologies such as Rapid Liquid Printing and techniques from soft robotics to achieve this adaptive material structure. In the past, scenarios like these have often required error-prone and complex electromechanical devices or complex molding/tooling to produce inflatables. Now we’re able to print complex inflatable structures with custom actuation and tunable stiffness.”

“This adaptive material technology points towards a future of transformable surfaces for adaptive human comfort, cushioning and impact performance”, says Martina Starke.

The Future Starts Here brings together ground-breaking technologies and designs currently in development in studios and laboratories around the world. Drawing upon international research, and working closely with a range of companies, universities, practitioners and advisors, the exhibition explores over 100 projects shaping the world of tomorrow.

ANALYSIS

This article discusses the ground breaking work being done by a MIT and BMW collaboration with adaptive material technology around structure building, here it discusses the use of pneumatic technology to create new materials. These materials can inflate and deflate to different desired adjustments and settings. BMW is interested in this for the future for customizing their cars for their users. I found that this work to be very interesting as it broadens the possibilities of the interior design of cars. For me, I think it make all my futuristic crazy ideas seem much more like a down the road possibility, it speaks in volumes about how fast technology is evolving and how quick people are working to see how it can be implemented in differing ways. These days, the imagination is just reality, with a question of when. This helps me to be more excited about creating crazy things, because chances are is there isn’t a way to do it now, there will be.