Plastic waste is one of the most urgent environmental issues of our time. Less than 10 percent of the plastic we use is recycled, and there’s currently an estimated 100 million tons of plastic in oceans around the world. But what would happen if we stopped thinking of plastic as waste, and instead as a valuable renewable resource?

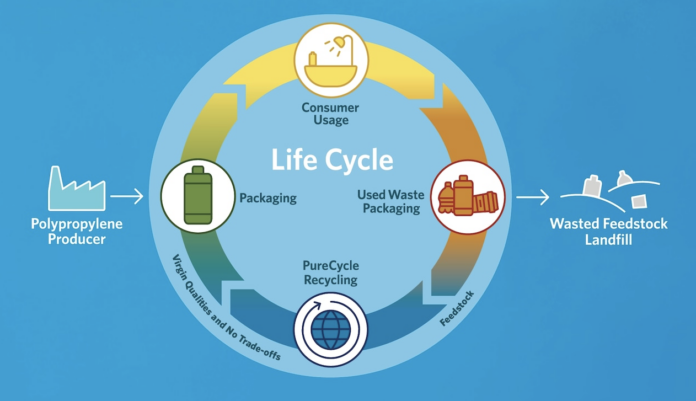

Scientists around the world want to find out. The plastic “end-of-life challenge” calls for new ways to recycle and reuse plastics endlessly in a closed loop system, so they never become waste. Innovation on that scale would convert the current “make-take-dispose” linear economy into a circular economy, where recycling plastic for eternity is possible.

John Layman, head of material science at Procter & Gamble and chief technologist and founding inventor of PureCycle Technologies, developed a revolutionary process to remove color, odor, and contaminants from polypropylene plastic waste and transform it into a “virgin-like” resin, which is the basis for plastic products. PureCycle’s technology presents a major development in recycling capabilities and focusing on polypropylene is especially notable. It’s the second-most used plastic in the world, yet only 1 percent is currently recycled.

Layman’s colleague and former classmate Scott Trenor, a senior polymer scientist at Milliken & Company, contributed a key set of plastic additives to increase the viability of PureCycle materials… Now Milliken and PureCycle are working together to scale and advance the technology, with plans to start commercial-scale production at PureCycle’s first plant, in Ohio, in 2021.

To recycle polypropylene into higher-value products, Layman knew he would first have to purify the plastic waste, and in an energy-efficient way. He worked on the discovery phase with financial backing from an internal seed fund program at P&G. The resulting PureCycle technology relies on a physical solvent-based process that uses less energy than a chemical process because it doesn’t have to break down and build up the molecule. “It’s the combination of the solvent choice, plus specific process steps, that enable us to purify this material in a way that nobody’s been able to do before,” he says.

The first PureCycle plant is expected to purify and recycle 119 million pounds of polypropylene and produce 105 million pounds each year. Those numbers sound huge, but Layman puts it in perspective by pointing out that 120 billion pounds of polypropylene were produced globally in 2018 alone. “You can see we have a long way to go,” he says.

Analysis

After doing some research on top of this article, I found that it is true that there is very little plastic that is actually recycled. It is sad and frustrating from a sustainability standpoint that even if you try to make a green and cleaner Earth, most of the time what you are doing doesn’t change anything. The company PureCycle is looking to change the way of recycling plastics. They have gone through different tests and projects to see how they can reuse them and make “new” plastics in a few different ways. I think that this project should be sustainable or at least it can use materials and things that were recycled or repurposed.

https://www.nationalgeographic.com/science/article/partner-content-innovations-in-recycling