(CNN)-What if doctors could just print a kidney, using cells from the patient, instead of having to find a donor match and hope the patient’s body doesn’t reject the transplanted kidney?

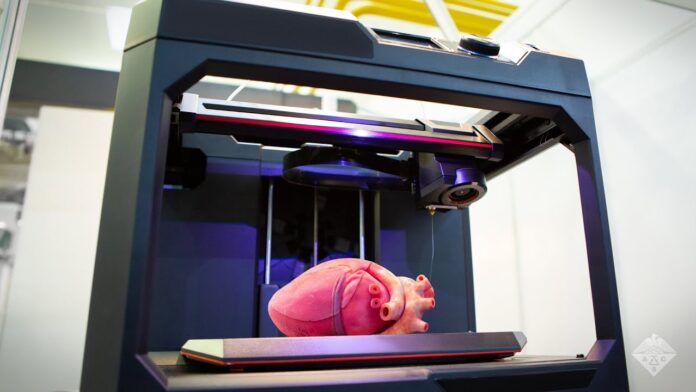

The soonest that could happen is in a decade, thanks to 3D organ bioprinting, said Jennifer Lewis, a professor at Harvard University’s Wyss Institute for Biologically Inspired Engineering. Organ bioprinting is the use of 3D-printing technologies to assemble multiple cell types, growth factors and biomaterials in a layer-by-layer fashion to produce bioartificial organs that ideally imitate their natural counterparts, according to a 2019 study.

This type of regenerative medicine is in the development stage, and the driving force behind this innovation is “real human need,” Lewis said.

Atala and his colleagues were responsible for growing human bladders in a lab by hand in 2006, and implanting a complicated internal organ into people for the first time — saving the lives of three children in whom they implanted the bladders.

“About a million people worldwide are in need of a kidney. So they have end-stage renal failure, and they have to go on dialysis,” Lewis said. “Once you go on dialysis, you have essentially five years to live, and every year, your mortality rate increases by 15%. Dialysis is very hard on your body. So this is really motivating to take on this grand challenge of printing organs.”

“There is no practical reason why anybody who needs a kidney — or a lung, a heart, a liver — should not be able to get one,” she added. “We’re using technology to solve this problem.”

…..

Analysis

This article was interesting to me because I had no idea 3D printing was being explored so in-depth in the medical field. I can see a lot of merit in using 3D printing for realistic surgery training and to think that 3d printing could potentially solve the issue of organ donation in the future is absolutely amazing to me. While this article does not inform on matters of 3D printing concrete, it can offer some insight into the broad range of additive manufacturing applications.

Take-Aways

Additive manufacturing has many capabilities and when pushed to its limits, new and amazing things are possible. Thinking outside the box is key.