Author: Mae Rice

Date: May 6th, 2021

Publisher: BuiltIn

Think of 3D printing as erosion in reverse. Bodies of water wear substances down layer by near-imperceptible layer; 3D printers build substances up in a similar way. Like all technology, of course, 3D printing isn’t nearly as old as the tides.

3D PRINTING COMPANIES TO WATCH

- Stratasys

- 3D Systems

- Relativity Space

- CELLINK

- Makerbot

- Stratasys

- nTopology

- Desktop Metal

- Protolabs

- Xometry

- Glowforge

The concept dates back to the early ‘80s, when Dr. Hideo Kodama almost patented it in Japan. He wrote some path-breaking papers on the hardening or “curing” of ultra-thin layers of liquid photopolymer under UV light, noting that this additive process could translate into speedy prototyping.

Due to a bureaucratic issue, though, Kodama’s patent never went through. Consequently, credit for 3D printing typically goes to Charles Hull, an American engineer who founded 3D Systems, the original 3D printing company, back in 1986. It made the first machines that could translate digital designs into 3D cured-resin artifacts.

These were 3D printers, though they could do only one type of 3D printing: stereolithography, a.k.a. resin-cooking. Since Hull’s breakthrough, other methods have emerged, including selective laser sintering (SLS), which uses laser light to solder microscopic layers of powder into a solid. That’s often how 3D-printing is done with metal.

Nowadays, 3D printing is a thriving industry. Modern printers range from desktop models to industrial giants to “bioprinters,” which can create human tissue. That’s not to mention the 3D-printing software, where objects get designed and optimized, and on-demand printing shops.

We’ve rounded up 20 companies that are thriving in the 3D printing space — including Hull’s 3D Systems, which is still going after all these years.

Relativity Space

Location: Inglewood, California

How it uses 3D printing: This 3D printing company fabricates rockets — fast. Relativity Space’s factory, Stargate, recently made the Terran 1, which the company claims is the world’s first fully 3D-printed rocket. It took just 60 days to make and launch, and required 99% fewer parts than a traditionally-made rocket. That’s due to 3D printers’ robotic agility; they can print intricate pieces as readily as simple ones. Another boost to the project: company engineers developed printable metal alloys specifically to withstand space travel.

Carbon

Location: Redwood City, California

How it uses 3D printing: Every 3D printing process involves fusing layers into a whole, but this company has reinvented the fusing process. Called Digital Light Synthesis, the technique smooths away the “seams” that 3D printing often produces. This creates a seamless finish, and a stronger product — traditionally 3D-printed objects’ strength can vary, depending on whether the nozzle moved clockwise or counterclockwise in production.

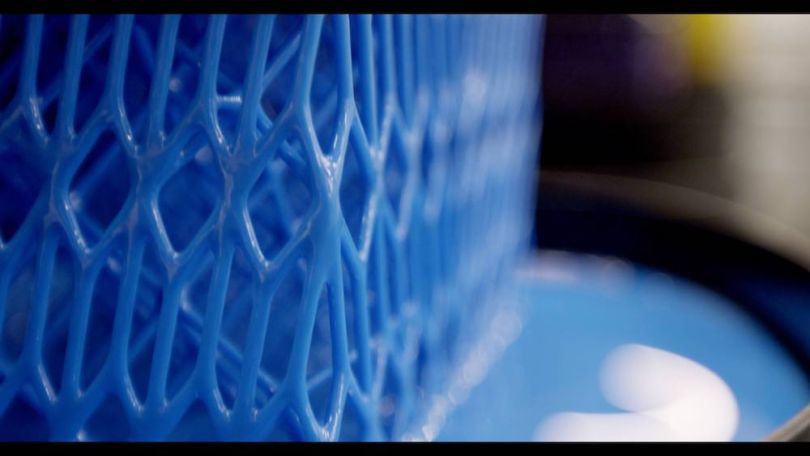

Formlabs

Location: Somerville, Massachusetts

How it uses 3D printing: This company makes four 3D printers, which range from desktop to industrial formats. The Form 3 and Form 3L, two of the smaller styles, rely on laser light and a flexible tank of resin to print quickly and precisely. Both can create features as narrow as one thousandth of an inch, which comes in handy for printing New Balance’s new midsoles. Made from a substance called Rebound Resin, these bouncy creations look less like traditional foam and more like sprays of Spiderman’s webbing.

Markforged

Location: Watertown, Massachusetts

How it uses 3D printing: Many 3D printers use plastic filament, but not those made by Markforged. Its industrial printers can print hardier substances, including nylon, carbon fiber and even metal — hence the “forge” in Markforged. (Continuing the metal theme, it also makes AI manufacturing software called Blacksmith.) Integrated into factories worldwide, this company’s printers reportedly have helped transform supply chains by accelerating prototype and replacement part manufacturing.

CELLINK

Location: Cambridge, Massachusetts

How it uses 3D printing: CELLINK focuses on “bioprinting,” the 3D printing of bone, cartilage, and, maybe someday, functioning human organs. Any and all of that is possible with the company’s patent-pending universal bioink — a soup of stem cells and alginate derived from brown seaweed. More than 700 labs worldwide currently use the substance. The company also makes complementary technology: 3D printers, software and specialty inks designed for specific types of tissue.

Divergent 3D

Location: Los Angeles, California

How it uses 3D printing: Divergent 3D aims to streamline and decentralize car manufacturing. That means moving production out of multi-million-dollar factories and into a networked cluster of 3D printing shops. In these smaller, warehouse-like spaces, the Divergent 3D team relies on end-to-end design software and industrial printers to create light, safe, fast cars. As of 2017, the company had prototyped two vehicle models: a motorcycle called the Dagger, and a sleek low-riding sports car called the Blade. (Cutting-edge, indeed!)

Makerbot

Location: Brooklyn, N.Y.

How it uses 3D printing: Though Makerbot printers have many industrial applications, the company also makes a newbie-friendly desktop printer, the Replicator+, that’s found in more than 7,000 classrooms. Makerbot complements that popular hardware with free lesson plans that incorporate 3D printers and are available via download or book form. In one suggested earth science lesson plan, for instance, students print models of different cloud types to literally grasp the distinction between cumulus and cirrus. And that’s just one of the new options Replicator+ opens up for students who learn best through touch and action.

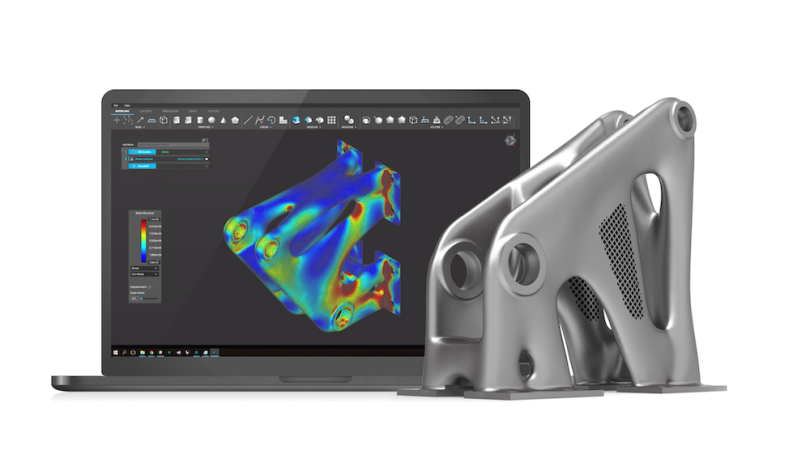

nTopology

Location: New York City

How it uses 3D printing: Focused less on 3D printing hardware than software, nTopology’s NTop Platform can be integrated into 3D printing engineering workflows. A standout feature: It can autonomously tweak and streamline existing designs, removing clunkiness and excess weight so designers can focus on more important problems and avoid busywork — whether they’re printing medical devices or rocket nozzles.

Shapeways

Location: New York City

How it uses 3D printing: Shapeways 3D prints designs on demand in a choice of more than 50 materials, including plastic, sandstone and platinum. Customers simply log in to the site, upload a design and place an order, which prints in one of the two Shapeways factories and arrives via mail. It’s online shopping, really, but instead of browsing the wares, shoppers design them. Shapeways also has a team of designers on hand to help users bring their visions to fruition.

3D Systems

Location: Rock Hill, South Carolina

How it uses 3D printing: The original 3D printing company remains on the cutting edge of the field. (Stereolithography inventor Chuck Hull also remains in a leadership position here — he’s CTO.)The team makes a broad spectrum of 3D printers, which work via stereolithography, a liquid-to-solid process, and a powder to solid process called selective laser sintering. Printers make everything from metal artifacts to plastic filaments to custom dental implants. 3D Systems also offers a constellation of related products, like 3D scanners and design software.

Glowforge

Location: Seattle, Washington

How it uses 3D printing: This company’s namesake 3D printer, Glowforge, can print with almost any material. Kid-friendly and intended for home use, it creates custom designs from plastic, wood and even chocolate. Though it allows for creativity, that’s not required; the hardware comes pre-loaded with a catalog of cool designs for everything from monogrammed macarons to a wooden Settlers of Catan game board.

Fast Radius

Location: Chicago, Illinois

How it uses 3D printing: Fast Radius has replaced old-school, centralized factories with a network of smaller “manufacturing lighthouses” — a move for which the company was named one of the globe’s leading factories by the World Economic Forum. At each of its fabrication plants, the company 3D-prints and injection-molds parts for industrial use and quickly ships them off. Its partnership with UPS, paired with the company’s distributed structure, means it can often offer next-day delivery, even on custom builds.

Mighty Buildings

Location: Redwood City, California

How it uses 3D printing: This startup has a minimal web presence — it’s still in stealth mode — but it focuses on 3D printed buildings. Specifically, Mighty Building makes tiny-house-esque “backyard studios” with a massive printer that barely fits in a warehouse. The company offers three studio models so far, which max out at less than 600 square feet. That’s smaller than many studios, but the pint-sized standalone structures are surprisingly stylish and functional, outfitted with floor-to-ceiling windows and working bathrooms.

Rokk3r Labs

Location: Miami, Florida

How it uses 3D printing: This startup accelerator-slash-consulting firm has helped more than 30 companies streamline their business plans with “exponential technologies.” (That means tech that helps them outperform competition by a factor of at least ten.) Those technologies include blockchain, Internet of Things connectivity, and, you guessed it, 3D printing. The latter can exponentially reduce the number of parts required in complex manufacturing, which accelerates and simplifies the whole process.

Mixed Dimensions

Location: San Mateo, California

How it uses 3D printing: This company specializes in 3D printing for gamers. Whether clients want custom board game pieces or 3D-printed replicas of their ship in the Star Trek video game, Mixed Dimension’s printer can make it happen. Capable of more than 10 million colors, it’s high-resolution enough for photo-caliber projects. Users can upload screenshots or CAD designs of their desired spaceship, or work with staff artists to turn imagined gaming tableaus into 3D realities.

Stratasys

Location: Eden Prairie, Minnesota

How it uses 3D printing: Stratasys has been in the 3D printing industry since 1988 — almost as long as 3D printing has existed. During that time, it has racked up more than 250 granted or pending patents worldwide. Today, the company helps clients like Audi and Lockheed Martin perfect their manufacturing process with 3D printing. It also manufactures printing hardware for Hewlett-Packard as well as its own brands. Ever the industry leader, Stratasys remains on the cutting edge, especially when it comes to recycling. Clients can send used cartridges, print engines and other parts back to the company for green disposal.

Protolabs

Location: Maple Plain, Minnesota

How it uses 3D printing: Protolabs speeds up the manufacturing process. As its name suggests, the business began as a quick-turnaround prototyping company. In 2014, however, it added a 3D printing shop to speed the transition between the prototyping phase and small batch testing. That shop now has more than 100 printers that can print metal, plastic and other materials.

Materialise

Location: Leuven, Vlaams-Brabant, Belgium

How it uses 3D printing: This company focuses on 3D printing software, which makes complex printing hardware accessible to engineers, healthcare professionals and even fashion designers. Designer Anoul Wipprecht, for example, used Materialise software to print a surreal, bubble-wrap-like dress that also tracks the wearer’s mood. The company’s comprehensive digital suite includes tools for drafting and optimizing designs, controlling printers mid-job and managing 3D printing workflows.

Xometry

Location: Gaithersburg, Maryland

How it uses 3D printing: Xometry began as a way to simplify prototyping. It software eliminated the need for companies to slowly and laboriously gather quotes from manufacturers. Instead, they could access six different types of 3D printers on demand and at instantly-quoted rates. That model has attracted high-profile clients like luxury car manufacturer BMW, which relies on Xometry for custom trim, logos and other unique and tooling-heavy touches that are printed from carbon fiber tubing.

Desktop Metal

Location: Burlington, Massachusetts

How it uses 3D printing: This company condensed a steel mill into a box smaller than a refrigerator that easily fits through an office door. No special ventilation is required, and there’s no open flame, laser light or loose powder involved. It just needs power and an internet connection to 3D-print with steel. More specifically, Desktop Metal’s printer extrudes rods of a powdered steel alloy, wax and polymer binder. (The company is developing copper and nickel filaments, too.) The printer first cooks away the binding. It then welds steel layers together in its furnace. Though it’s a very contained process, it’s also transparent — users can watch it unfold via live stream.

Images via Shutterstock, social media and company websites.

https://builtin.com/hardware/3d-printing-companies

Comment:

This article really helped visualize where the 3D printing industry is right now and what different companies are doing with it. There are a plethora of different companies with different innovations that are pushing the envelope of 3D printing.

One of the most interesting is Materialise, which printed a dress. Things like this and others are pushing the boundaries and allowing 3D printing to get into the hands of more and more individuals.