Honda has a long history of corporate excellence driven by an enduring philosophy of “joy.” It believes in creating joy for its customers when they buy, for its dealers when they sell, and for its associates and suppliers when they create. The automobile maker has always invested in solutions to ensure that it never has to compromise on quality, compliance, and security, believing this helps the company expand its work beyond making cars to bringing life-enriching values to its stakeholders.

Honda began to explore digital technologies and smart manufacturing in 2013 with the launch of its second manufacturing unit in India, it partnered with Infosys. Infosys worked with Honda to design and implement systems that helped it deliver joyful experiences. Their solutions around optimizing export processes, parts traceability, and production planning helped bring harmony in the creation process. Each vehicle is handled by different departments as it passes through the assembly line. As production volumes and manufacturing capacity grew, it was important to continue to maintain the expected quality benchmarks and standard operating processes. Honda implemented a quality-control information system to identify the defects on a real-time basis and ensure quality delivery of vehicles to its customers.

A single automobile can have as many as 20,000 different parts. It is critical to keep track of each of these to ensure compliance with industry regulations and standards. Infosys implemented an IoT-enabled part traceability system for the ferrous shop floor, thereby reducing manual efforts significantly.

Infosys also helped Honda with a dealer-planning system focused on on-time car delivery. “The biggest change has been in the way that these platforms have brought digital technology to the shop floor,” Honda Car India VP Hilal Isar Khan said. “Right from the management, to the employee actually assembling the automobile, these systems have changed the way Honda employees interact with, and respond to, technology.”

Digitization in automobile manufacturing will only grow. Companies will adopt blockchain technology for part traceability, build completely automated manufacturing plants and invest in manufacturing execution systems. It is clear Honda will continue traveling along on its digital transformation journey in a post-COVID world—to ensure it continues to build high-quality cars and deliver joy to all its stakeholders.

ANALYSIS

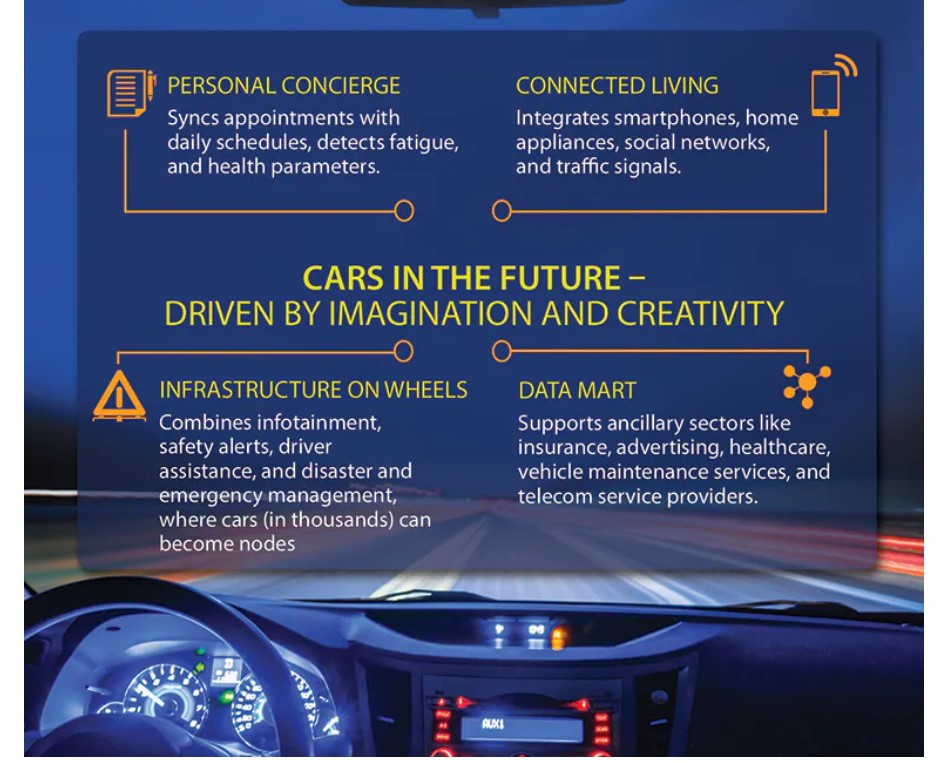

This Article discusses Honda’s move into the digital technologies and smart manufacturing, with the launch of its second manufacturing unit in India, it partnered with Infosys. Infosys worked with Honda to design and implement systems that helped it deliver joyful experiences, which they hold to be a very important aspect of their products. The article goes into some detail of the goal of these smart technologies and how they achieve that. As nearly everything in our life becomes more and more digital, it opens plenty of doors for opportunity. When I consider designing a fully autonomous vehicle, there is a great deal of need and opportunity for this exact thing. Some research on my part has show the prediction of at the future car having the treatment of a living room on wheels; this means a space for media, entertainment, games, and community. To achieve this, it’ll likely be introducing a lot of technology, especially when I think about my own design ideas that look at customization of one’s personal vehicle.